We design, develop and deliver technologies that help ensure your beers, spirits or extracts are the very best they can be.

Meurastream

Meura has always developed innovative technologies and equipment offering competitive advantages to brewers.

These different technologies and equipment are gathered in the Meura brewhouse and have all been specially designed to provide exceptional performance in terms of yield, brightness, productivity and wort quality.

The Meurastream: Reducing steam consumption by 52%!

The industrial introduction of the Meurabrew (Meura’s continuous brewhouse) is certainly one of the major technological developments in the recent history of the brewing industry. To date, 4 large size continuous brewhouses have been sold or installed. The Meurabrew is a very attractive solution for large breweries with a limited number of different wort streams and certainly in the case of greenfield projects where utilities still have to be installed. Consequently, this also means that it is not the optimum solution for every project. Thus, both types of brewhouse will continue to exist in parallel.

Batch- as well as continuous- brewhouses still have significant steam consumption and an over-production of hot water. In the last 5-10 years especially, the over-production of hot water has become a problem for many brewers. Since the industry is trying to reduce the water consumption of the overall process, the extra hot water produced in the brewhouse cannot be used or only partly. Often, the hot water tank in the brewhouse overflows on a daily basis which represents a loss of water and energy.

With reduced steam use and hot water excess in mind, Meura has developed a new concept, called the “Meurastream”. The Meurastream principle can be implemented in a batch brewhouse as well as a Meurabrew.

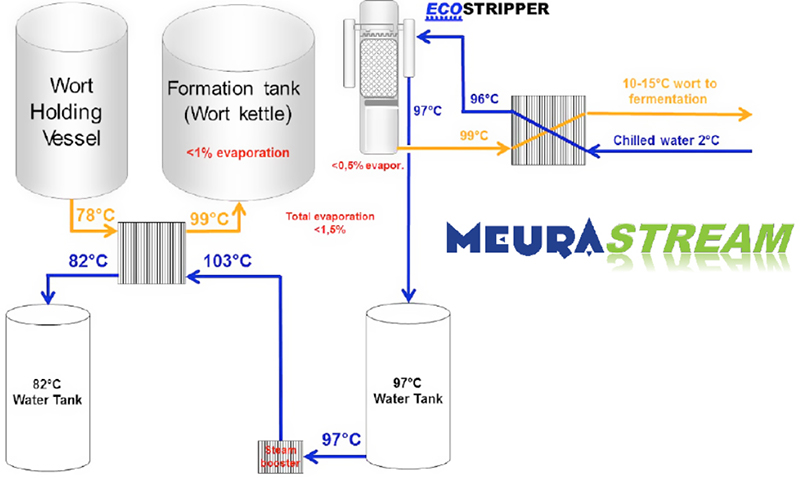

The following diagram shows the principle of the MeuraStream:

This Meurastream consists of 2 major technologies:

- Brew water recovery at high temperature with energy re-use

The principle of the Meurastream is very straightforward. Part of the energy from the wort cooling process is used to pre-heat the wort. Instead of heating the brew water in the wort cooler to 80-85°C, the water will be heated to about 96°C. This means that the volume of this hot water will be smaller than at the usual lower temperature. The energy from the steam injected into the Ecostripper is partially recovered and heats this water further to 97°C. The hot water is than temporarily stored in a very hot water vessel. For the next brew, this 97°C water is heated to 103°C with an in-line steam booster and is used to pre-heat the wort to 99°C, when pumped to the wort kettle (or formation vessel). The temperature of the brew water will be lowered from 97°C to 82°C, which is then used for mashing-in and sparging. In short,part of the energy from the wort cooling is used for pre-heating the wort. - ECOstripper technology

With the Ecostripper, the heat treatment of the wort and elimination of volatiles is separated into two steps (in a classic brewhouse the wort kettle performs these processes at the same time). In a first vessel, called the formation vessel, the wort is kept at 100°C with almost no evaporation (less than 1%). In this step, all processes that involve heat treatment are performed (formation of DMS, sterilization, enzyme deactivation, hop isomerisation etc.) After this formation step, the trub is eliminated by a whirlpool or Clarisaver (wort settling tank). The final step, in-line with the wort cooling, is the ECOstripper, a wort stripping technology. Wort is pumped on top of the stripper and in counter-flow 0.5% steam is injected to eliminate the unwanted volatiles. The overall evaporation rate is thus only 1.5%!

The following table compares the Meurastream with a brewhouse without energy recovery and one with the conventional vapour condensation technology (often called the “pfaduko” system). The calculations are made under the same conditions and recalculated to 15°P cold wort.

| Classic Brewhouse | Pfaduko Brewhouse | MeuraStream | |

|---|---|---|---|

| Thermal energy | 26,0 MJ/hl | 19,4 MJ/hl | 12,6 MJ/hl |

| Excess in hot water | 37,8 l/hl | 37,8 l/hl | 15,6 l/hl |

The table shows that the Meurastream reduces the thermal energy of a brewhouse by 52% without energy recovery and 35% for a brewhouse with pfaduko! Excess hot water is reduced by 60% thanks to the Meurastream! These figures mean that the MeuraStream is probably the most energy- efficient brewhouse concept available on the market. The MeuraStream concept can be easily implemented in an existing brewhouse.

Watch our video here !